MTEK FLUX Ballistic

Extended undercut geometry. 100% screwless. Entire system under 1 kilogram!

Bonowi introduces the FLUX Ballistic Helmet , the newest tactical head protection from MTEK USA . It is the result of many years of design and development work. The result: one of the most advanced, modular helmet systems on the market.

The word FLUX is an acronym for Future, Lightweight, Undercut, eXpandable and is derived from latin fluxus, meaning “flow”. Every aspect of the FLUX has a very specific and deliberate purpose while maintaining design continuity- everything “flowing” together. On the surface it may appear to be a standard helmet, however once underneath, you’ll see it is like none other.

100% Boltless shell

There are no drilled holes or inserts through the FLUX helmet to weaken the underlying ballistic material. Polymer fasteners replace all the heavy bolts, screws and other steel mounting hardware. Fastener strikes and secondary spalling are no longer an issue. Lightweight retaining structures are bonded directly to the outer shell to allow for accessory rail and shroud removal. The end result is a safer, lighter-weight helmet.

High-strength

High tensile strength structural adhesive permanently bonds the polymer retaining structures to the outer shell. Maximum surface area between surfaces yield exceptional bond strength and has outstanding performance throughout a wide environmental range.

Modular

The suspension and retention are attached to the shell independently of any exterior fasteners. If your mission requires absolute minimum weight this unique feature allows you to strip the FLUX without needing to sacrifice ballistic or impact protection.

Removable

Thermoplastic anti-rotation inserts provide you the option to remove your accessory rail if servicing or maintenance is required. Should the total applied force to the accessory rail exceed safety limits, the fasteners will fail, allowing the rail to break away from your helmet shell preventing neck or head injury.

Flux Ballistic

Description:

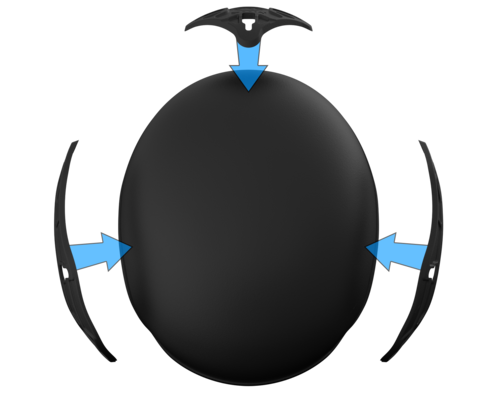

The Flux Ballistic is the cornerstone of the innovative MTEK helmet system . This helmet has been specifically designed to offer you the highest level of safety, comfort and modularity currently available in a modern ballistic helmet. The lightweight shell is made from high-performance polyethylene fibers and features an undercut geometric profile that follows the natural shape of your head for exceptional stability and coverage. In addition, all removable fasteners have been designed for maximum strength and weight savings to further reduce the overall weight of the system.

The FLUX Ballistic has a 100% boltless shell. There are no cuts or holes in or through the ballistic material, ensuring maximum ballistic performance. The high-cut edge profile has been designed to be compatible with a wide range of existing communications headsets and accessories. Lightweight polymer support structures are bonded to the outside of the FLUX shell and provide a secure mounting platform for the FLUX M‑LOK accessory rails and the Wilcox L4 shroud. Different variations of ballistic side and lower jaw covers will be available soon to further increase your helmet’s protective coverage if required.

The Fluxliner™ interior provides excellent impact protection and is made from a proprietary, shock-absorbing foam. Each helmet comes with two sets of adjustable comfort pads that allow you to customize the interior to your head. The retention system also features Cam-Loc sliders for easy adjustment and a suede chin cup. The ends of the mount feature Inverseclips® for easy detachment and added security.

specifications

- Total weight: 1,000 grams

- Ballistic shell: 500 grams

- Minimum operating weight: 800 grams

- Ballistic protection area: 1,058 cm²

- Overall dimensions: 267 x 241 x 165 mm

Ballistic shell

- Protection class IIIA (NIJ 0106.01−0108.01)

- Extremely light: 500 grams

- 100% screwless (including accessory rails, shroud and retention system

- Ballistic material with no seams or penetrations (no internal seams or weak points)

- The geometry adapts to the natural shape of the head

- Large side cutout for communication headsets

- Available in Coyote, Black, Green, Multicam®

FLUX M‑LOK Rails

- Accepts Magpul® M‑LOK accessories

- Glass fiber reinforced polymer construction

- Low profile with anti-snag design

- All connections to glued holding structures of the helmet shell via anti-twist nuts

- O2 center release buckle (CRB)

- Horizontal and vertical M‑LOK negative mounting surfaces

- Removable spacers for upgradeable protective cover

- Multiple attachment points for routing communications or power cables

- Removable for maintenance or additional weight reduction

flux liner:

- Manufactured using a proprietary shock absorbing foam for superior impact protection

- Multiple comfort pads to customize fit and minimize pressure points

- Moisture-wicking fabric

- Meets ACH impact requirements*

- The design promotes air circulation around the head

restraint system:

- Lower rear mounting points for maximum stability

- Chin cup made of suede offers pleasant comfort

- Cam-Loc sliders for one-handed adjustment and a secure fit

- Inverse Clip® for customization or removal of the mount

Wilcox Industries L4 Shroud:

- Glass fiber reinforced polymer frame

- Machined anodized aluminum bracket

- Low profile with anti-snag design

- Anodized aluminum fasteners

Additional scope of delivery

- Velcro® fields for mounting patches, IR strobes and counterweights

- operation manual

- helmet bag