The MTEK helmet system

Innovation redefined.

Bonowi introduces the MTEK helmet system.

It is often said that necessity is the mother of invention: MTEK USA was founded on this principle.

The military experience gave the company founders a special perspective for the development of their products. Individual gear has evolved significantly over the years, but it hasn’t always been like this. “Upgraded” used to mean more weight.

MTEK has been successful on the market for over 16 years. The developers do their best, always striving to improve and push the limits of what is possible. They draw motivation from the sacrifices made by their sisters and brothers in arms.

This drives the people of MTEK USA to constantly innovate and strive for perfection.

Ballistic Helmets

Impact protection helmets

lightweights

High-strength polymers are used extensively in the FLUX and STRIKE – in fact, 68% of the FLUX Carbon helmet and 96% of the FLUX Ballistic are made from a polymer fiber. As graphic shows, the FLUX Ballistic System contains a very small amount of metal. Actually, when comparing total weight, less than 2% of either helmet consists of ferrous or non-ferrous metal. This equates to substantial weight savings making it one of the strongest, lightest-weight helmets available today.

Carbon in %

Ballistic in %

Advanced Geometry

The MTEK helmet system follows the natural shape of the head

The first thing you feel when putting on an MTEK helmet is how it hugs your head. The geometry of the outer shell is the most important factor in the design of a helmet. This is because all other features must follow this “primary reference body” in one form or another. MTEK helmets are designed to conform to the natural shape of your head, resulting in greater comfort and stability even when you wear the helmet for hours or attach accessories. This helps to actively reduce mental and physical fatigue.

Hundreds of variations and revisions have gone into the “MTEK shell” design, because a better helmet starts with a better helmet shell!

side view

The rim profile of the “MTEK shell” is designed to be compatible with all headsets, goggles and respirators. The rear profile allows for proper clearance when you’re wearing a ballistic vest and does not restrict movement even when lying in the prone position.

Ergonomics

The “MTEK shell” was designed to fit snugly to the head and has a distinct undercut on the outer shell. This deviates from the traditional designs that have a tendency to “flare out” at the base of the shell. This design is simpler to manufacture, but disadvantageous for wearing comfort.

Undercut

The underside of the “MTEK shell” extends further down and pulls into the middle. This lowers the rear mounting position of the retention system, and allows the suspension system to further cradle your head. This adds significantly to the overall stability of the helmet, especially when carrying large night vision goggles or other mounted accessories.

Uncompromising Protection

The most modern materials and processing technologies are used in the manufacture of each individual MTEK helmet. This is done in the pursuit of providing you the highest performing helmet system available today. For example, additional carbon fiber has been added to further increase the shell rigidity and impact performance of the FLUX Carbon. Only the latest generation of polyethylene fibers are used for the FLUX and STRIKE Ballistic, which provide the highest level of ballistic protection.

One shell, multiple helmets

If you want to expand the protection area of your FLUX or STRIKE helmet shell, we have the right thing for you. The MTEK helmet system has several variants of additional side panels, giving you several different helmet styles for the price and comfort of one. These covers attach seamlessly underneath the side rail mounts, allowing for maximum accessory space or “rail estate”. The covers were designed to overlap the shell edge providing you increased protection should a fragment or slug impact anywhere along the seam. The covers, as well as the mandible and visor system, will be available after the release of the FLUX Ballistic helmet. Like the FLUX shell, all additional components are also available in the “Carbon” (carbon fiber) and “Ballistic” protection levels.

Wilcox L4 Shroud

The L4 represents what some would call the “gold standard” of shroud design. It has a low profile, anti-snag geometry and features an anodized 6061 insert that accepts all of your optical devices and cameras. This rock-solid mount is precision manufactured by Wilcox Industries in their state-of-the-art manufacturing facility.

The FLUX bolt-less configuration is maintained even with the Wilcox L4 shroud. It is connected to the front support structure with lightweight, anodized 6061 screws secured with nylon washers to keep the cover stable and under proper tension. The three t‑nuts represent the highest “volumetric mass density” of any fasteners contained in the FLUX helmet (basically, they’re the heaviest fastener of the helmet). Their combined weight is a little more than four US one dollar bills (4.73g).

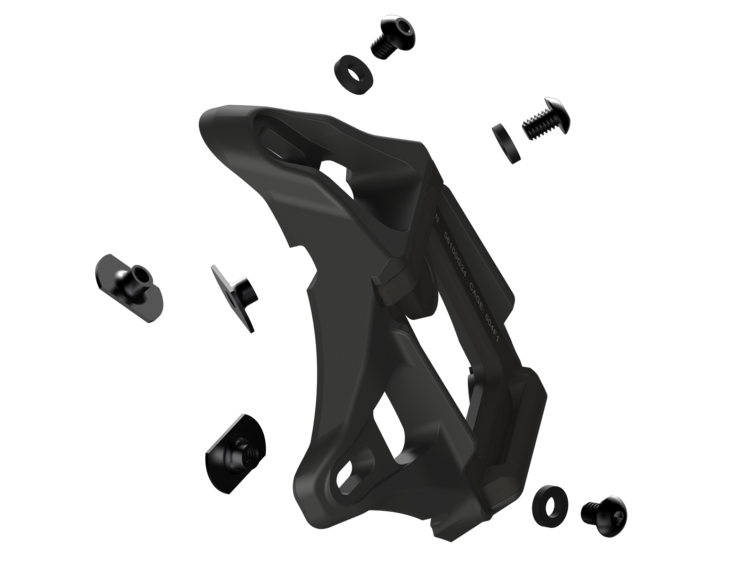

FLUX Accessory Rails

The flat helmet rails offer the MTEK helmets an endless variety of possible accessories and attachments. The rails utilize the proprietary Magpul® M‑LOK slots found on your favorite black rifle. There are multiple tie-down points available when routing cables over or around the helmet. The O2 clip port is compatible with most existing center release buckles. The stable 3‑point mounting system provides a rigid, adaptable platform for mounting a variety of accessories and devices.

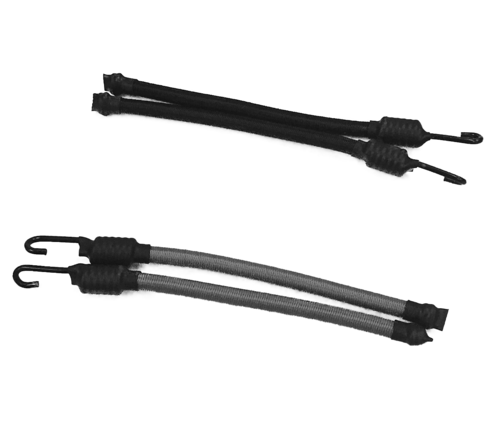

Each set of rails ships with a pair of Battle Bungees. Ideal for additional stabilization of, for example, night vision devices or for temporarily attaching lens caps or covers for mounted devices and accessories.

The accessory rails are fully compatible with the M‑LOK system. Designed by Magpul, these direct attachment slots allow you to hard mount a wide range of accessories to your helmet.

The M‑LOK Accessory Rail includes a lightweight spacer that you can remove to expand the helmet’s area of protection with additional ballistic side panels.

Built Tough.

These rails, like the rest of the MTEK helmets, have been engineered for maximum performance. They’re molded from a semi-crystalline aromatic polyamide resin that ensures moisture and chemical resistance over a wide range of temperatures and environments. Reinforcing ribs have been applied to all major stress points to further part rigidity and decrease flex. All unnecessary material has been removed from the rails and spacer to keep weight to an absolute minimum.

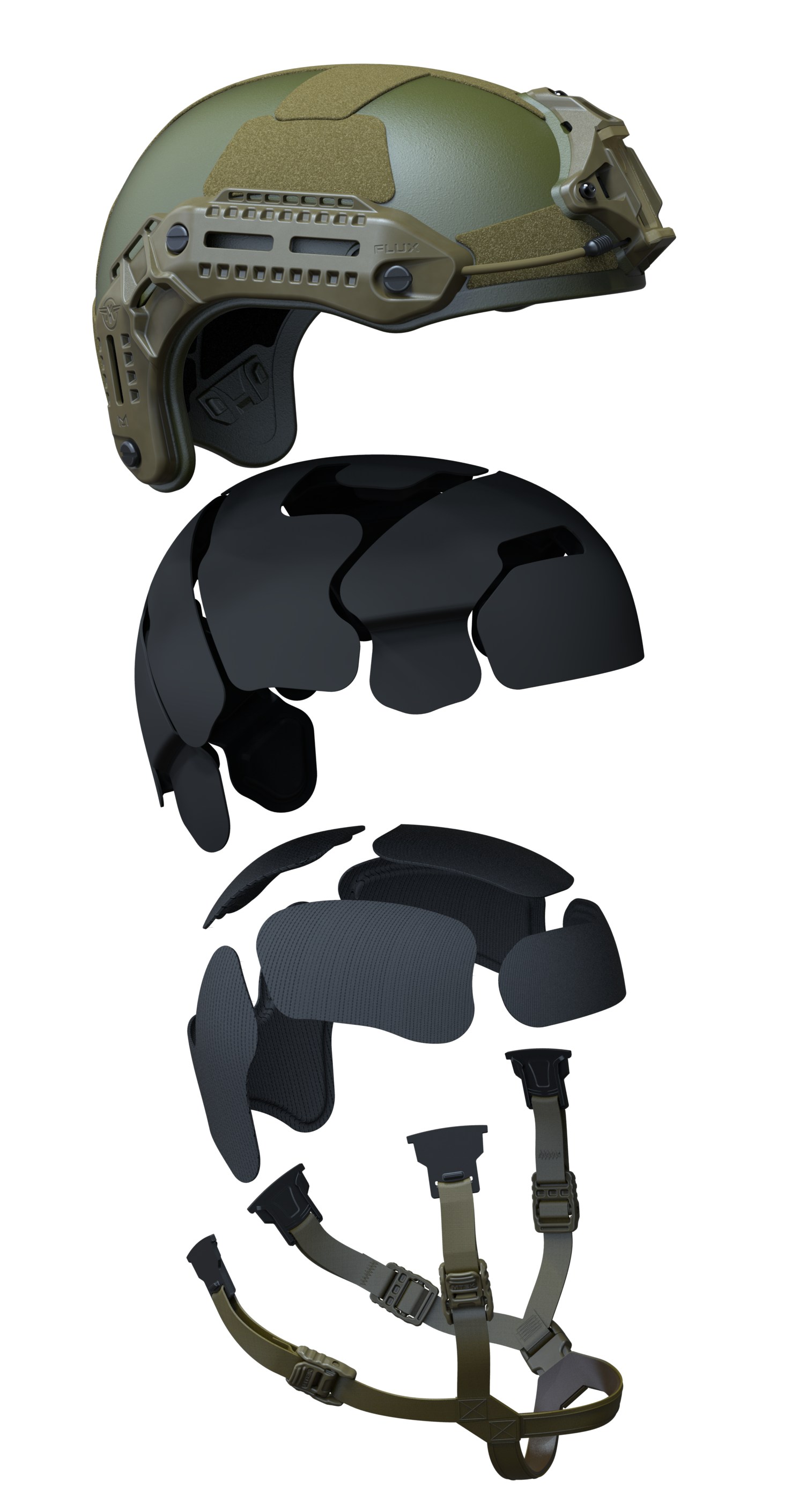

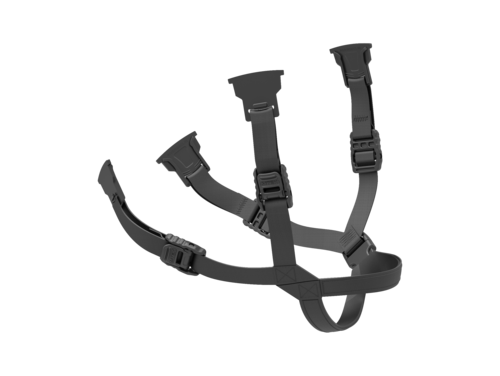

Fluxliner Suspension, Cam-Lock Retention

The Fluxliner™ gives the MTEK helmet a soft, tailored fit and superior stability that your old helmet was missing. It’s manufactured using a proprietary rate-sensitive foam that has excellent impact performance. In addition to the impact liner, each FLUX helmet includes two sets of multi-thickness comfort pads that allow you to manage the interior layout to get that perfect, custom fit. Cam-Lock retention with Inverseclip® make for a hassle free installation and sizing. The back retention mounting points have been lowered to the bottom extent of the shell for maximum four-point stability. This design feature allows for the elimination of the nape strap, resulting in a simplified, lightweight retention.

Impact Liner

Made from a viscoelastic foam, the Impact Liner is designed to provide maximum impact protection while promoting airflow in the Carbon and Ballistic versions of the MTEK helmets.

Comfort Pads

The comfort pads are repositionable and allows you to custom fit the Fluxliner to the exact topology of your head. Each FLUX ships standard with two sets of comfort pad sizes ensuring a precise fit.

Retention System

Maximum helmet stability is ensured by using a four-point retention. Cam-Lock sliders allow you to quickly adjust the tension, even while wearing the helmet. Chin cup is lined with suede leather for incredible comfort.

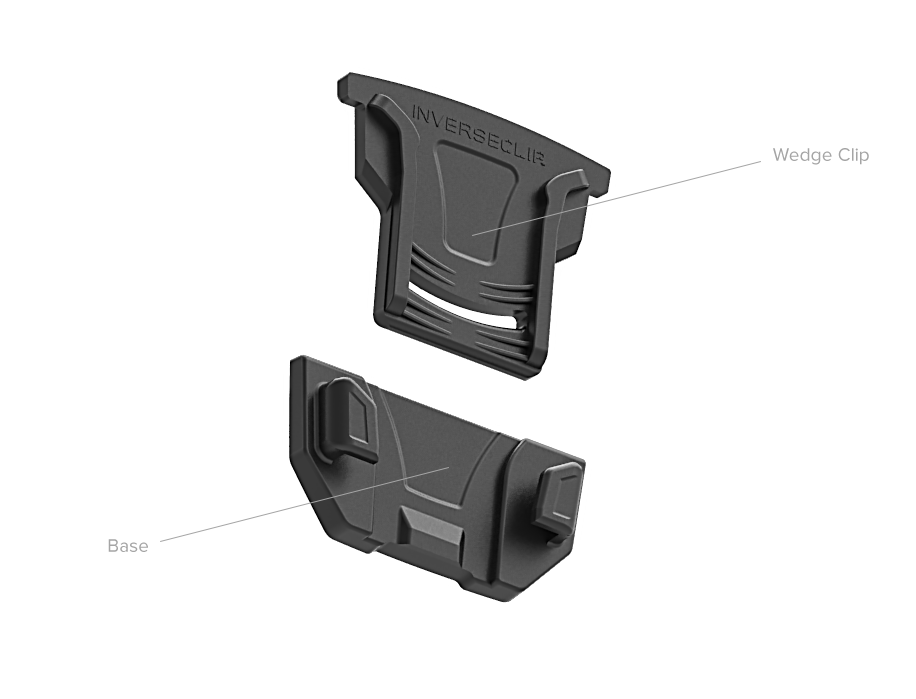

Featuring the Inverseclip®

With the Inverseclip® from HelmetComp you can quickly and easily remove the harness from the FLUX helmet shell. It consists of a two part design comprising of the wedge clip and the base, both manufactured from high-performance, engineering grade polymer. The retention system (webbing) is connected to the wedge clip, and the base is bonded to the interior of the helmet shell using the same high performance adhesive found in the outer shell retaining structures.